💯Pure physical principles💯

No harmful by-products from the process

BAO's Pride

|

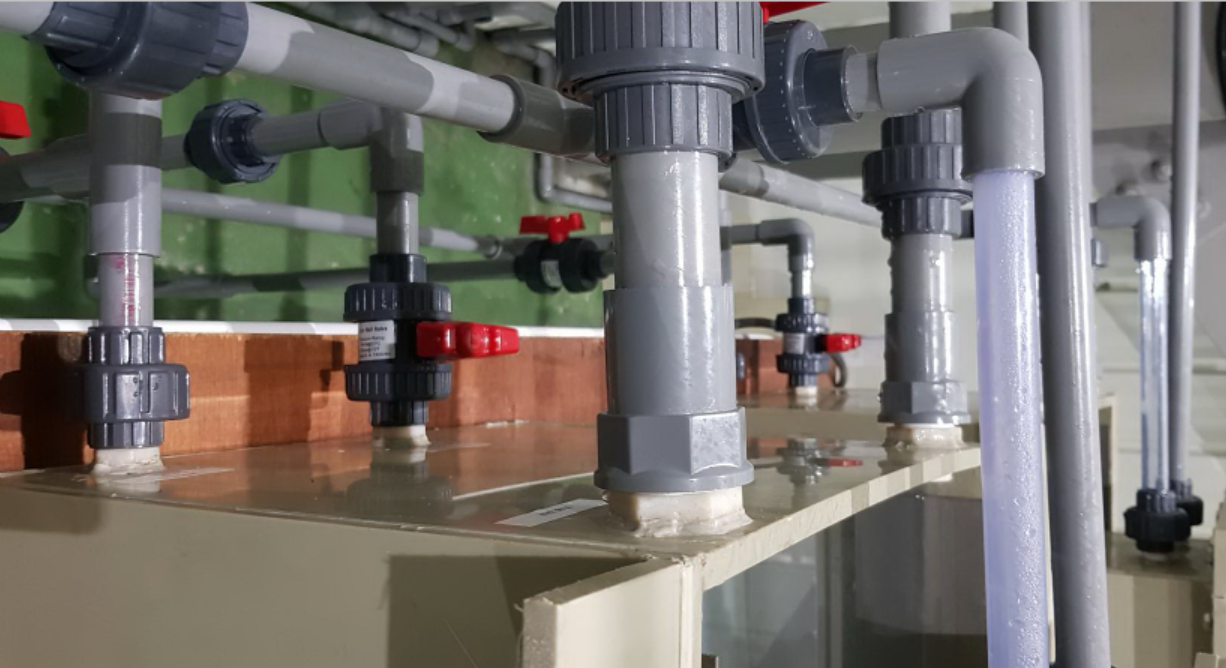

Electrolytic Tank Electrolysis

Electrolysis mechanism through the diaphragm electrolyte solution for electrolysis, and produce ClO2 gas process.

Online monitorThrough the fully automatic rectifier, the built-in ORP and PH meters can monitor the production process at any time, making operation more convenient and quality control more transparent.

|

BAO's proudest aqueous electrolytic ClO2 solution manufacturing equipment.

👉 The ClO2 aqueous solution equipment is made by a special gas-liquid fusion technology by oxidation reduction of ClO2 gas in the electrolysis mechanism of the unique research and development of electrolysis.

👉ClO2 gas has bactericidal effect, so it is widely used in drinking water, food disinfection, environmental medication and industrial sewage treatment, etc. In recent years, it has been further applied in cooling cycle system, aquatic freshness and aquaculture.

👉Due to pure ClO2 gas is dangerous, it is usually mixed with ClO2 and dissolved in a liquid to make an oxidizing agent in the form of an aqueous solution, to reduce the risk and easy to carry.

👉In general, the practice of mixing the aforementioned gases and liquids is usually to pour the gas into a closed space, because the liquid stored in the closed space is not moving, so the gas and the liquid can only contact through the liquid surface. And because the gas must be dissolved in the liquid to reach a certain concentration, the aqueous solution will have a better effect, so the static mixing method will spend a lot of time waiting for the mixing, and its manufacturing efficiency is low.

👉 Therefore, this core technology enables a good gas-liquid mixture and a more efficient electrolytic manufacturing equipment.

👉 The ClO2 aqueous solution equipment is made by a special gas-liquid fusion technology by oxidation reduction of ClO2 gas in the electrolysis mechanism of the unique research and development of electrolysis.

👉ClO2 gas has bactericidal effect, so it is widely used in drinking water, food disinfection, environmental medication and industrial sewage treatment, etc. In recent years, it has been further applied in cooling cycle system, aquatic freshness and aquaculture.

👉Due to pure ClO2 gas is dangerous, it is usually mixed with ClO2 and dissolved in a liquid to make an oxidizing agent in the form of an aqueous solution, to reduce the risk and easy to carry.

👉In general, the practice of mixing the aforementioned gases and liquids is usually to pour the gas into a closed space, because the liquid stored in the closed space is not moving, so the gas and the liquid can only contact through the liquid surface. And because the gas must be dissolved in the liquid to reach a certain concentration, the aqueous solution will have a better effect, so the static mixing method will spend a lot of time waiting for the mixing, and its manufacturing efficiency is low.

👉 Therefore, this core technology enables a good gas-liquid mixture and a more efficient electrolytic manufacturing equipment.